Laboratory Applications

There are several requirements for laboratory's compressed air:

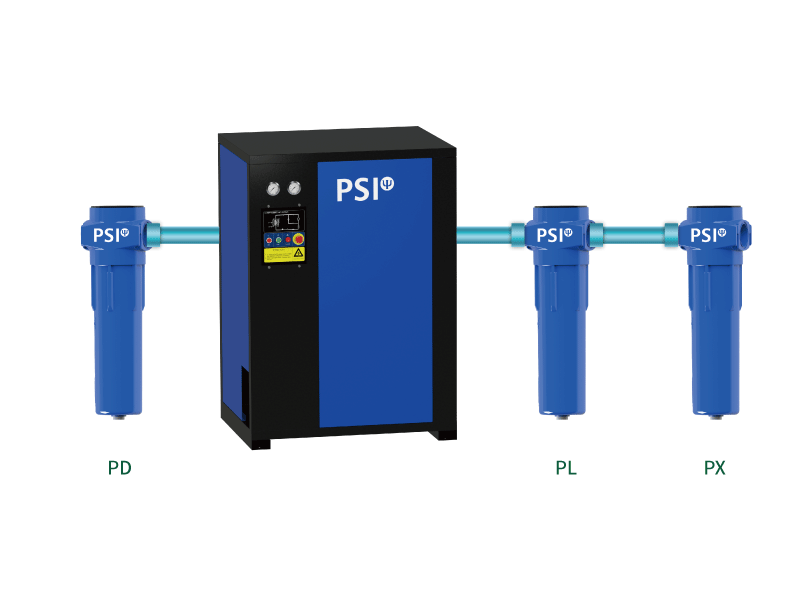

Purification. Laboratories usually require dry, oil-free, dust-free, and odor-free compressed air, this usually requires equipment such as filters, dryers, and pressure regulators to ensure the purity of compressed air.

Stability. The laboratory has high requirements for the stability of compressed air, as it requires testing under different speed and pressure conditions. The stable pressure and flow rate of compressed air are usually achieved through methods such as multi-stage compression, local pressurization, and jet control. At the same time, it is necessary to ensure the stability of parameters such as temperature and humidity of compressed air, avoid errors, and ensure the accuracy of experimental data.

Less Noise. For certain types of laboratories, such as analytical instrument laboratories, the noise of the air compressor should be controlled below 60 decibels to maintain a quiet working environment.

Pressure & Flow. The air pressure of most laboratory air compressors is adjustable from 0 to 8 bar, which meets the air pressure requirements of general experimental equipment. For small pneumatic equipment, the pressure is generally around 6 kilograms, and the exhaust is 10OL/MIN.

Dryness. For certain precision instruments or special experiments, there are strict requirements for the dryness of compressed air, such as dew point below -40 ℃.

Cleanliness.The air cleanliness should reach a particle size of less than 0.01um, or even reach a sterile level.

Product Application